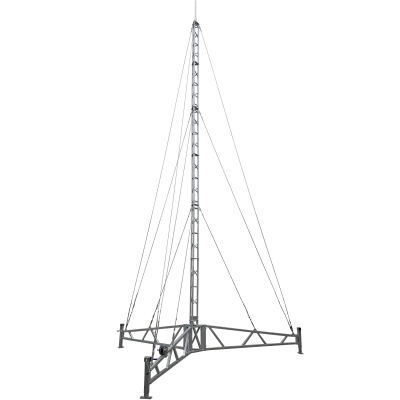

- Lightweight winch-up design

- Heavy duty galvanised tripod outrigger base

- <1 hour setup time

- 11 m total height (9.3 m lattice)

- 220 mm wide body (180 mm faced)

- 3100 mm section lengths

- Quick, simple winch raising (winch included)

- Low maintenance aluminium construction

APAC's tripod-base aluminium lattice towers are manufactured locally in Queensland in 3.1 metre sections allowing effortless transport, meaning total leadtime can be measured in days - not weeks or months. Constructed with a bolt-together galvanised tripod and lightweight aluminium modules, this tripod tower is designed to be assembled by hand with just a few basic tools.

Able to be set up in under an hour with a team of two, APAC's tripod tower allows instant communications anywhere - no footing required. The bolt-together design means easy shipment to site, and the included winch allows raising and lowering of the tower eliminating the need for tower climbs.

This unique portable lattice tower consists of three bolt-together heavy duty galvanised outriggers, a 1.0 m galvanised base, three 3.1 metre lattice sections, guy wires, anchor footings/skids, and your choice of headframe. APAC's aluminium lattice tower features three upright columns made from 42x3 CHS with 25x3 CHS lattice welded in between by certified boom welders, providing incredible strength while retaining a lightweight design that can support your technician to climb the full 11 metre height.

AL220 Tripod Tower is suitable for operation in wind speeds up to 160 km/h by anchoring the tripod legs using pegs or blocks to provide dead weight.

Capable of mounting a range of lighting, CCTV, sensors, and industrial monitoring equipment, this serviceable mast is incredibly popular in mining and construction where climbing structures can present a safety concern, eliminating the need for an elevated work platform or a certified tower rescue team to perform even simple adjustments. This mast is also ideal for combination with wind turbines, providing high elevation with maximum stability allowing the establishment of temporary power generation at your exploration site, construction office, or hardstand.

Headframes are available to support a range of telecommunications configurations from standard ABAB/ABCABC multipoint, to a full LTE eNodeB. Torque Arms (anti-twist) available for applications requiring large microwave antennas, or systems with large offsets.

Engineering Compliance

- Aluminium fabrication in accordance to AS1664

- Aluminium welding in accordance to AS1665

- Steel fabrication in accordance to AS4100

- Steel welding in accordance to AS1554.1

- 7/16" and M12 Grade 8.8 bolts compliant to AS1252

- Guy cables in accordance to AS3569, Class 7x19 Grade 2070

- Guy wire preload tension to 1.0 kN

- Cable joins and attachments in accordance to AS2579

- Structure classification per AS3995 is Type II

- 140 kg payload @ Wind Region A1 to A5 (44.5 m/s (160 km/hr)), using 275 kg dead weight/anchor uplift per leg

We're confident this tower is one of the best designed and safest in the world. Contact our team today to discuss your application.