Machine Overview

The Baoma BM500 is a Closed-loop EDM Wire Cut machine used for extreme high precision machining and the creation of complex and intricate metal structures.

Explanation

EDM (Electro Discharge Machining) is a cutting process that uses a spark erosion wire to perform non-contact cuts in metal parts. The process uses an electrical discharge that forms an arc between an EDM wire (typically Molybdenum) and a work piece to erode or remove metal in its path. Because EDM wirecutting apples no cutting forces to the workpiece and applies little or no heat it can be used to cut extremely intricate, finely detailed parts in a range of thin and thick metals.

EDM machines such as the Suzhou Baoma BM500 are controlled by computer numeric control (CNC) and programming is accomplished directly off 2D CAD data or 3D models.

Advantages

- High precision linear guideway.

- Two step-motors to produce U and V movement, permitting four axis (X, Y, U, V) simultaneously movement.

- Direct upload of AutoCAD .dxf file format

- Double direction Intelligent Auto wire tension system

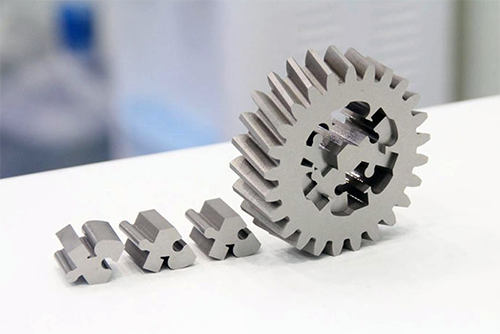

Examples