- Globoid (Double Eveloping Worm)

- Spiral Bevel

- Hypoid

- Spur Gears

- Helical Gears

- Worm Wheels & Shafts

- Internal Splines & Keyways

APAC provide a wide range of gear cutting services right here on the Sunshine Coast, from simple spur, helical bevel, and face drive gears, to precision and difficult to manufacture globoid and hypoid types. There is no type of gear we cannot manufacture. With in-house 3D CAD modelling, APAC can design and produce CNC precision components, vehicle gears, differential gearing, internal gears, and custom-made gears.

Materials used to produce gears include steel which is the most common material, and various nonferrous materials including plastics and composites.

Globoid - Double Enveloping Worm Gears

For transmitting power between two non-parallel and non-intersecting shafts a worm gear is used. In single enveloping worm gear design, the contour of the gear teeth is modified in such a way that the amount of the contact surfaces increases. This provides increased accuracy from the worm gear. With a single enveloping design hundred percent engagement is there only for the central thread and all side threads only have partial engagement.

To overcome this problem a double enveloping design is used. In double enveloping worm gear, the teeth profile of the gear as well as the shape of the worm threads are modified, creating an hourglass shape, to achieve greater engagement.

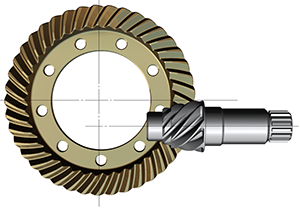

Hypoid & Spiral Bevel

A spiral bevel gear is a bevel gear with helical teeth, commonly seen in vehicle diffs where the direction of force applied from the driveshaft must be turned 90 degrees to drive the wheels. A hypoid is a type of spiral bevel gear whose axis does not intersect with the axis of the meshing gear. The shape of a hypoid gear is a revolved hyperboloid - that is, the pitch surface of the hypoid gear is a hyperbolic surface, whereas the shape of a spiral bevel gear is normally conical. Hypoid gearings are used in power transmission products that are more efficient than conventional worm gearing. As with globoid designs, hypoids are considerably stronger in that any load is conveyed through multiple teeth simultaneously.

As one might expect the introduction of a hyperbolic surface increases manufacturing complexity significantly. Fortunately this presents no challenge to APAC who have the machining technology and years of experience with hypoid gear cutting.