Characteristics

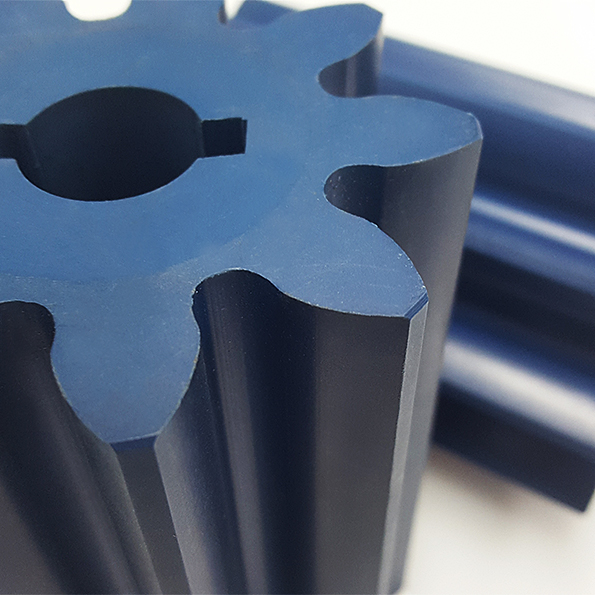

Polyphenylene sulfide is an engineering plastic, commonly used today as a high-performance thermoplastic. PPS can be molded, extruded, or machined to high tolerances. This reinforced, internally lubricated polyphenylene sulphide grade demonstrates an excellent combination of properties including wear resistance, load-bearing capabilities and dimensional stability, when exposed to chemicals and high temperature environments. Techtron® HPV PPS finds its applications where PA, POM, PET, PEI and PSU fall short or where PBI, PI, PEEK and PAI are over-engineered and a more economical solution must be found.

Thanks to the uniformly dispersed internal lubricant, Techtron® HPV PPS exhibits excellent wear resistance and a low coefficient of friction. It overcomes the disadvantages of virgin PPS caused by a high coefficient of friction, and of glass fibre reinforced PPS which can cause premature wear of the counter face in moving-part applications.

- Excellent wear resistance

- Low coefficient of friction

- Chemical resistance

- Load bearing capabilities

- Dimensional stability

Applications

High-performance, demanding industrial components such as chemical process equipment, pump, valve and compressor components, high temperature insulators, brush holders, industrial drying and food processing ovens, bearings, and rollers.

Technical Specifications

The guaranteed minimum mechanical properties of Techtron® HPV PPS, extruded are shown below.