Characteristics

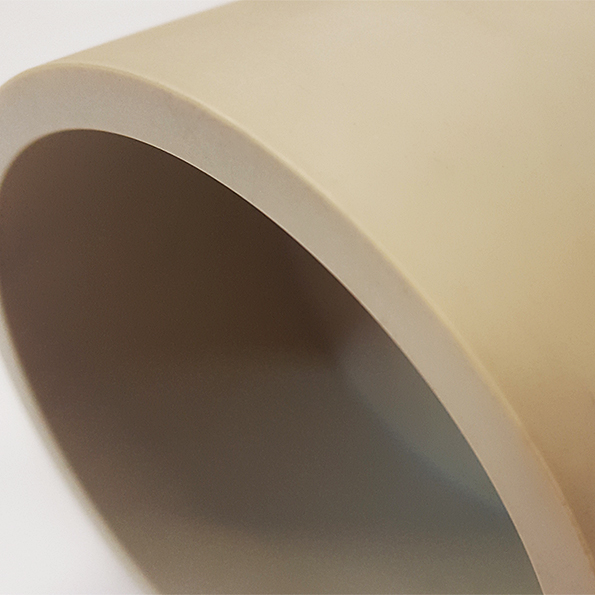

Polyether ether ketone (PEEK) is a colourless organic thermoplastic polymer in the polyaryletherketone (PAEK) family, used in engineering applications. The KETRON PEEK family of materials is based on polyetheretherketone resin. This semi-crystalline advanced material exhibits a unique combination of high mechanical properties, temperature resistance and excellent chemical resistance making it the most popular advanced plastics material. KETRON PEEK 1000 stock shapes are produced from virgin polyetheretherketone resin and offer the highest toughness and impact strength of all KETRON PEEK grades.

The composition of the raw materials used for the production of the KETRON PEEK 1000 natural stock shapes complies with the directives of the European Union and with the American FDA regulations concerning plastic materials intended to come into contact with foodstuffs. These features, added to its excellent sterilisability by means of steam, dry heat, ethylene oxide and gamma radiation, make this grade very popular in medical, pharmaceutical and food processing industries.

- High mechanical properties

- Temperature resistance

- Excellent chemical resistance

- High impact strength

Applications

High-performance, demanding industrial components such as electrical industries, coil bobbins, insulating bushings, housings, process equipment, milking machines, pumps, valves, filtration plates, heat exchangers, food processing / Medical industries, components subjected to repeated cleaning and sterilisation.

Technical Specifications

The guaranteed minimum mechanical properties of Ketron 1000 (Polyetheretherketone PEEK) are shown below.