Machine Overview

The Hartford LG-1000 F1 VMC is a Linear Guide Vertical Machining Centre.

Explanation

CNC Vertical Machining Centers (VMCs) remain a machine shop fundamental. The machine is designed for both milling and holemaking on a variety of non-round or prismatic shapes. The primary types of machining centers are either vertical or horizontal. The vertical type is often preferred when work is done on a single face. With the use of rotary tables, more than one side of a workpiece, or several workpieces, can be machined without operator intervention. Vertical machining centers using a rotary table have four axes of motion. Three are lineal motions of the table while the fourth is the table’s rotary axis.

Advantages

- Rapid feed rate of 40, 40, 32 m/min for X, Y, Z axes reducing non-cutting time and directly increase productivity.

- The rigid one-piece bed and wide column base are heavily ribbed to prevent twisting and distortion under even the most severe cutting forces.

- Meehanite cast iron contributes to unparalleled damping characteristics.

- Efficient oil and fluid separation incorporated on casting design prevents cutting fluid deterioration.

- Once-piece casting design integrates chassis and chip disposal opening with base.

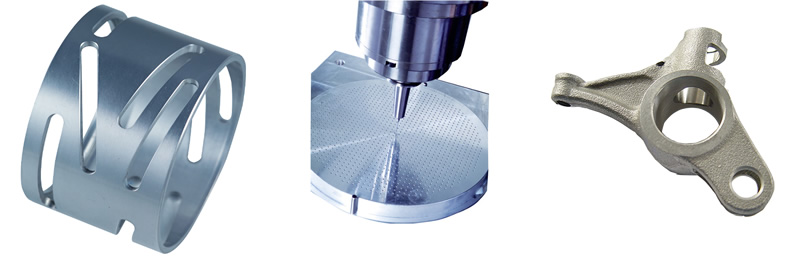

Examples