Catalog

Beach Infrastructure

In addition to our world class height systems, APAC provide SLSA Beach services for Australia. Our small but hardworking team includes qualified sheet metal and boilermaker tradespersons. We're a local, friendly company that's proud to be building Australia.

We provide aluminium, galvanised, and stainless steel fabrication services, which are combined with water-jet cutting, multi-axis CNC machining, EDM wirecutting, and a huge range of machine shop services to provide one of the most innovative manufacturing facilities on the coast.

- ATV Wheels

- solid 50mm galvanised axle with stainless slip over

- stainless U bolts

- 75x50x3 6061 drawbar

- Galvanised Hitch

- Optional safety chain

- Aluminium wheels

- Stainless hardware supplied with carbon grease

- High quality Australian made product

- Full custom builds available;

- Road/ATV Wheels

- solid 50mm galvanised axle

- Galvanised eye to eye leaf springs

- 125x60x10 6061 drawbar

- Aluminium wheels

- Drainable Bouy/cone storage area in rear

- Fully enclosed washable beach side

- Stainless hardware supplied with carbon grease

- High quality Australian made product

- Full custom builds available;

- Light Weight Aluminium

- loads and unload both directions

- removable drawbar

- drawbar can be placed at both ends

- Aluminium mag wheels

- off road beach wheels

- solid 40mm stainless steel axles

- 22 rollers

- 800kg carry weight

- towable by SSV

- handles for emergency launch

- Model 1 high end build

- Aluminium Mag wheels with aggressive 22/11/10 tyres

- solid 50mm galvanised axles

- 101x50x10 6061 drawbar

- galvanised hubs with marine bearings and seals

- Stainless hardware supplied with carbon grease

- High quality Australian made product

- Full custom builds available;

- Base Design Model 2 economical

- open layout

- drainable flooring

- all aluminium

- Aluminium Mag wheels with aggressive 22/11/10 tyres

- solid 50mm galvanised axles

- 101x50x10 6061 drawbar

- galvanised hubs with marine bearings and seals

- Stainless hardware supplied with carbon grease

- High quality Australian made product

- Full custom builds available;

- Model 3 budget friendly

- Aluminium Mag wheels with aggressive 22/11/10 tyres

- solid 50mm galvanised axles

- 75x50x6 6061 drawbar

- galvanised hubs with marine bearings and seals

- Stainless hardware supplied with carbon grease

- High quality Australian made product

- Full custom builds available;

- All Aluminium

- Dual Axle LT tyres

- electric brakes

- Galvanised Axles

- optional Motor lift and holder

- optional removable board racking for mutiple use trailer

- optional colours available

- loading ramp

- side access doors

- Stainless hardware supplied with carbon grease

- High quality Australian made product

- Road Wheels

- solid 50mm galvanised axles

- Galvanised eye to eye load sharing leaf springs

- 125x60x10 6061 drawbar

- Aluminium wheels

- Optional Drainable Bouy/cone storage area in front

- Spare wheel

- Stainless hardware supplied with carbon grease

- High quality Australian made product

- Full custom builds available;

- Marine-grade aluminium construction for maximum corrosion resistance

- Hinged-base design for effortless servicing and rapid deployment

- hinged mast

- Rigid, vibration-stable structure suitable for elevated camera and comms payloads

- 200W high-efficiency solar array mounted on the mast head

- Victron MPPT solar charge controller for superior energy harvest

- 80Ah lithium battery bank providing long-duration autonomy in low-sun conditions

- Road Wheels

- solid 50mm galvanised axle

- 4/5 IRB Hulls, 4x Engine mounts,

- internal lighting.

- Victron solar

- 125x60x10 6061 drawbar

- Aluminium wheels

- Drainable flooring

- Spare wheel

- Stainless hardware supplied with carbon grease

- High quality Australian made product

- Full custom builds available;

- Aluminium Construction

- powder coating available

- 12mm gussets

- mounts to factory bolt positions

- retains factory winch mounting holes

- 50x4 end tubes

- Additional IRB engine mounting plates supplied for SLSA clubs

- Auto Brake Winch

- RBW2500-16

- Load Max 1135 kg

- Gear Ratio 11.1 to 1

- Cable 6.35 mm x 17 m

- Weight 6.3kg

- Aluminium 75x50x6 RHS strong but lightweight

- 3.8m drawbar extension, can be modified to suit your club

- saves your SSV from rust

- 2 person carry handles

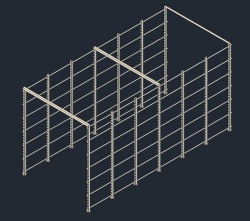

- Fully adjustable design to suit any club or operational environment

- Supplied in 2.5m to 3.5m upright configurations with horizontal slides up to 6.5m in length

- Uprights bolt securely to existing concrete via 4x 10mm Dynabolts

- Horizontal tubes slide effortlessly into position and pin off at either end for a clean, rigid finish

-

High quality Australian-made product

- Fully modular design to safely store and transport 1–4 IRB outboard motors.

- Available in single, dual, triple, and quad configurations to suit 25hp Tohatsu or equivalent engines.

- Built from high-grade aluminium with smooth edges and heavy-duty welds throughout.

- Optional lockable castor wheels for workshop mobility or fixed installations.

- Compact footprint and balanced weight distribution ensure safe loading and unloading.

- Aluminium construction

- Solid beach wheels

- no metal components so it wont rust

- lightweight

- 270L full

- marine grade Aluminium

- 800kg castor wheels

- 500mm Deep, 900mm Long, 600mm Wide

- No welding required – assemble on site with basic tools

- Built for Australian conditions – galvanised or powder-coated finishes

- Fully modular – hundreds of layout options

- Ideal for concrete, timber or steel structures

- Industrial strength – suitable for commercial and high-traffic environments

- Corrosion-resistant for coastal areas

- 150x75x6mm 6061 t5 aluminium

- 12mm base plate and gussets

- Any sizes

- Bolt together designs available for postage

-

Assessment of Damage: Initially, a thorough examination of the tiller arm is necessary to understand the extent of the damage. This helps in planning the repair process effectively.

-

Grinding and Cleaning: The damaged area is ground out to remove any fractured metal and to create a clean, fresh surface for welding. This step is crucial for ensuring that the welding adheres properly. Along with grinding, all paint and corrosion around the damaged area are removed to ensure a clean metal surface.

-

Welding Process: The tiller arm is then carefully welded back together. This requires precision and skill, especially given the nature of the material (typically aluminum for these tiller arms). The welding must be strong enough to withstand the operational stresses.

-

Reinforcement: To reinforce the repaired area and provide additional strength, a piece of 6005 T5 6mm aluminium is incorporated. This step is essential to ensure that the tiller arm can withstand the high-stress conditions of racing or patrolling without failing again.

-

Finishing: After the welding and reinforcement are completed, the area is typically ground smooth, and any necessary finishing touches are applied. This might include repainting the tiller arm to protect it from corrosion and to match the original look.

-

Quality Check and Testing: Finally, a thorough inspection and testing of the repaired tiller arm are necessary to ensure that the repair is successful and the arm is safe to use.

- Can Am Defender, Yamaha Viking, Kawasaki Mule

- full rust treatment and removal

- replacement sections cut out and welded back in if required

- anti corrosive paint applied over chassis

- full chassis lanolin coating

- brake replacement optional

- gets the vehicle back to a safe and operational condition

- Wear and Tear on Equipment: Vehicles like RWCs, SSVs, Tractors and IRBs require regular maintenance to stay operational. The saltwater exposure can corrode metal components and cause mechanical issues if not addressed.

- Infrastructure Maintenance: Roller doors, storage areas, and other club facilities need lubrication, repairs, and upkeep to ensure smooth day-to-day operations. Clubs often struggle with sourcing replacement parts for their specific needs.

- Safety and Compliance: Ensuring all equipment—such as rescue gear and first aid kits—meets the necessary safety standards and regulations is essential.

- Skills Maintenance and Training Equipment: Manikins, rescue boards, and other training equipment degrade over time and need regular upkeep

- Environmental Impact on Facilities: Coastal clubs experience constant exposure to sand, wind, and moisture, accelerating wear on infrastructure. Managing rust, mould, and general degradation is a continuous process.